Why do laptop motherboards fail over time?

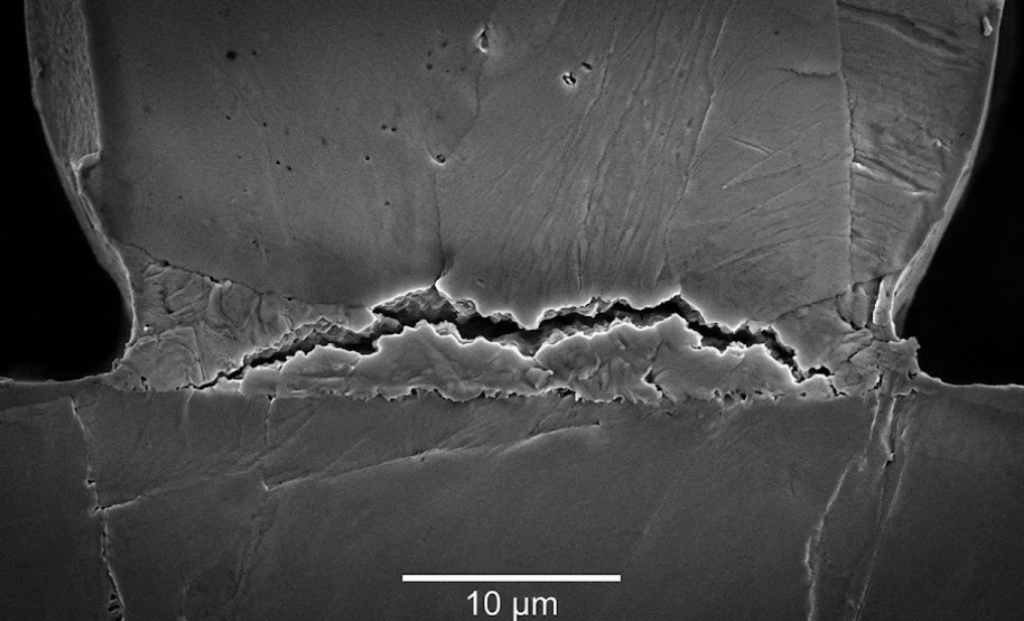

Most motherboards fail due to motherboard solder joint failure triggered by thermal cycling. As components heat and cool, the “SAC305” lead-free solder expands and contracts at different rates than the PCB. This creates microscopic cracks and brittle “Intermetallic Compounds” (IMC) that eventually snap the electrical connection between the CPU and the board.

The RoHS Shift: Why Modern Solder is Brittle

In the early 2000s, the electronics industry shifted from lead-based solder to lead-free alternatives like SAC305 (Tin-Silver-Copper). While environmentally friendly, this shift introduced a significant reliability challenge. Lead-free solder has a higher melting point and is physically stiffer than its leaded predecessors.

Because SAC305 is less “compliant,” it cannot easily absorb the mechanical stress caused when a laptop chassis flexes or when a CPU expands under load. Instead of bending, the solder joint accumulates microscopic “fatigue damage.” Over years of use, these tiny stresses coalesce into motherboard solder joint failure, often appearing as a “dead” laptop that won’t turn on or a GPU that artifacts during gaming.

The IMC Layer: The “Glue” That Becomes the Weakest Link

When solder meets the copper pad of a motherboard, a chemical reaction occurs, creating an Intermetallic Compound (IMC) layer. This layer (typically Cu6Sn5) is essentially the “atomic glue” that holds your computer together.

However, the IMC is a double-edged sword. While necessary for a bond, the IMC layer is inherently brittle. In the presence of high heat—common in systems lacking 32GB RAM thermal protection—this brittle layer continues to grow. As it thickens, the joint loses its ability to withstand vibrations. Eventually, the connection doesn’t just fail; it “shatters” at the atomic level, a phenomenon known as interfacial fracture.

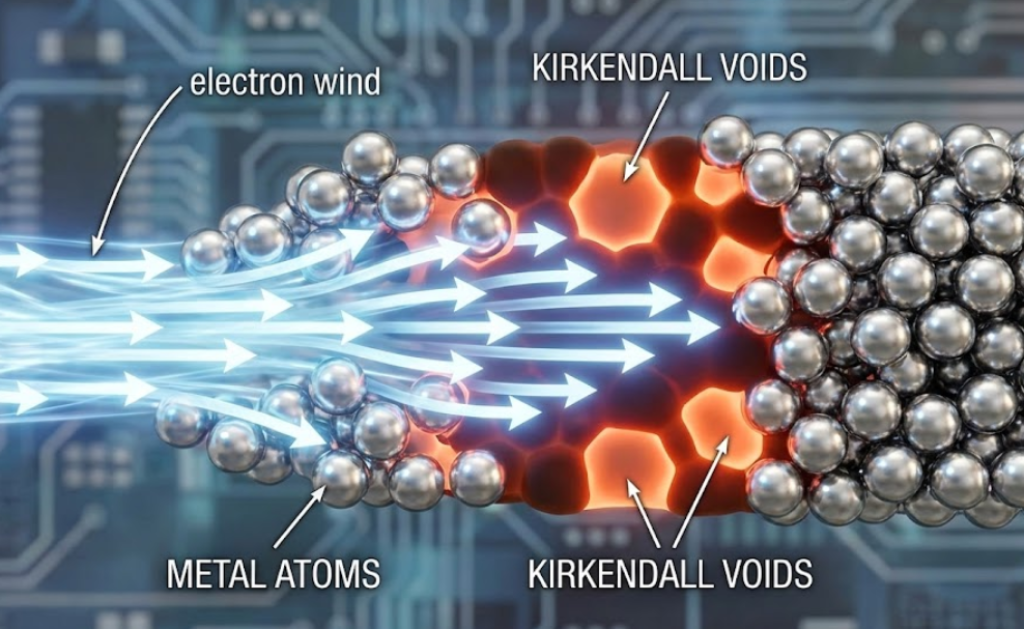

Kirkendall Voids and Electromigration: Internal Erosion

Beyond external heat, the electrical current itself can destroy a solder joint from the inside out. This process, known as Electromigration, occurs when the “electron wind” physically pushes metal atoms in the direction of the current.

- Atom Displacement: Over thousands of hours, atoms move away from the “source” side of the joint.

- Kirkendall Voids: As atoms move, they leave behind microscopic holes called Kirkendall Voids.

- Circuit Thinning: These voids reduce the effective thickness of the joint, increasing electrical resistance and generating even more heat.

This internal erosion is why a high-performance laptop might work perfectly for three years and then suddenly fail under a normal workload. The “pipes” carrying the electricity have simply been thinned out until they can no longer handle the current.

Thermal Cycling: The Mechanical Stress of “Delta T”

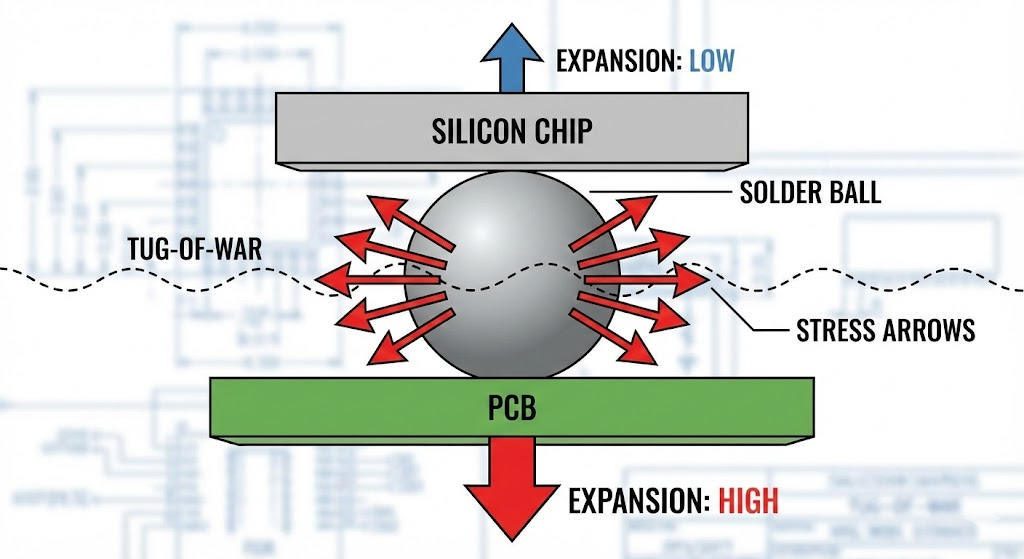

Every time you turn your laptop on and off, you are performing a thermal cycle. Because the silicon chip, the solder, and the fiberglass motherboard have different Coefficients of Thermal Expansion (CTE), they expand by different amounts.

- Silicon: Expands very little (2.6 ppm/°C).

- PCB: Expands significantly (15–20 ppm/°C).

- Solder: Stuck in the middle, it is pulled in both directions.

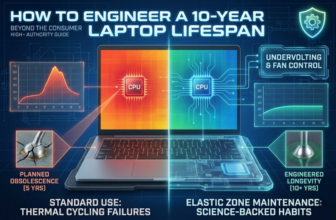

This “tug-of-war” is described by the Coffin-Manson relation. The larger the temperature difference (Delta T), the faster the solder joint reaches its fatigue limit. This is the scientific reason behind our laptop lifespan engineering advice: by keeping your temperatures stable through undervolting and proper cooling, you are literally preventing the mechanical “stretching” that snaps your motherboard’s joints.

Frequently Asked Questions (FAQ)

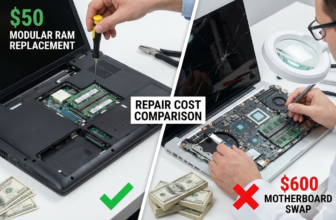

Yes, through a process called BGA Reflowing or Reballing. However, as we discussed in our guide on soldered RAM repair costs, the high heat required for repair can often cause further damage to the delicate PCB laminates.

No. Coil whine is usually caused by the physical vibration of inductors. However, excessive vibration over many years can technically accelerate solder fatigue in surrounding components, though it is rarely the primary cause of failure.

Statistically, yes. Gaming laptops undergo much larger and more frequent “Delta T” swings (jumping from 40°C at idle to 90°C during gaming), which puts them on a much faster track toward motherboard solder joint failure than a cool-running business machine.

Conclusion: The Future of Interconnect Reliability

Motherboard solder joint failure is the invisible wall that limits the lifespan of modern electronics. While we cannot change the laws of metallurgy, we can control the environment that accelerates these failures. By choosing business-class hardware with underfill reinforcement and maintaining a strict thermal budget, you can ensure that your computer’s “atomic glue” stays intact for a decade or more.